- Polypropylene spinning machine

- Polypropylene FDY equipment

- Polyester POY spinning machine

- Polyamide FDY common and high strength equipment

- Polyester FDY equipment

- Polyester high strength equipment

- polyester、Polyamide、 Polypropylene BCF equipment

- Small spinning machine

- All kinds of spinning special parts

- What is polypropylene spinning machine equipment

- Accelerate circular innovation in the textile industry to help enterprises better embrace the international market

- | Professionals need to think deeply about how to make themselves indispensable talents of enterprises!

- Kashgar textile and garment industry (Guangzhou) investment promotion meeting was held in Guangzhou

- High quality polypropylene FDY spinning machine looking for Fubon

- Contact:Mr. Huang Guofu

- Cel:0086-13901505556

- Fax:0086-519-83341119

- Email:czfb5556@126.com

- Add:No. 288-8 ChangLi Rd, Huangli Town, Changzhou, JS PRV.

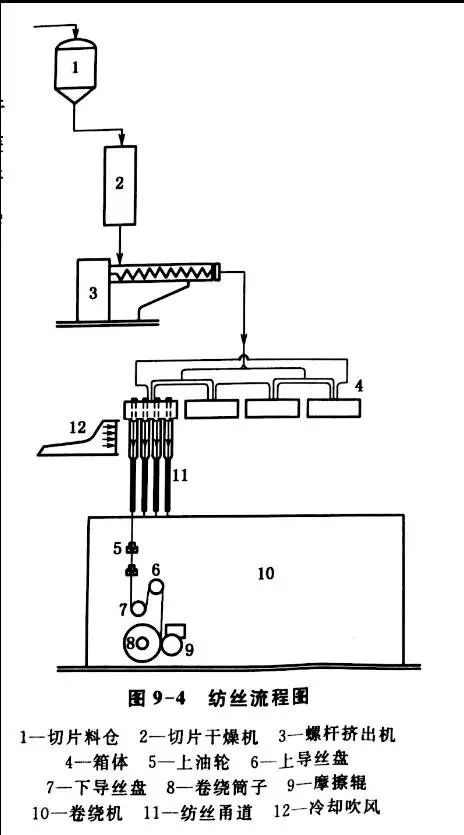

The term spinning is well known, How many people can understand the process, Xiao Bian today for everyone to introduce!

Conventional spinning process is as follows: dry slice → melt extrusion → mixing → metering → filtration → spinning → cooling forming → oiled → winding → UDY cheese. Details see below:

1, melt extrusion

Slice relying on gravity from the feed into the screw extruder. Due to the rotation of the screw, the chip moves forward along the screw channel, and the heating element is installed on the outside of the screw rod sleeve to transfer the heat to the chip through the sleeve. At the same time, the friction between the chips in the screw extruder is squeezed The heat. The slices are heated and melted, and are compressed by the extruder to have a certain melt pressure.

2, mixed

The static mixer is used to mix the melt at the outlet to enhance the uniformity of the melt and reduce the difference between the tube wall and tube center temperature and the residence time when the melt passes through the tube. If the melt is uniform, no static mixer can be used.

3, measurement

The melt output from the screw extruder is measured by a metering pump assigned to each spinning station by a distribution pipe to ensure that the linear density of the yarn is uniform and the strips dry uniformly. At the same time, metering pumps can melt the melt pressure to meet the needs of high-pressure spinning.

4, filter

Pre-spinning filter material such as sand filter out the melt impurities. Filter materials are emery, sea sand, ultra-fine glass beads, filters and so on. In high-pressure spinning, the filter layer will have a higher resistance, the melt friction heat, temperature, improve the rheological properties of the melt.

5, spinning

After filtration, the melt is dispensed to the various spinneret holes on the spinneret and discharged from the spinneret to form a melt stream.

6, cooling forming

The melt stream is cooled down by the cooling medium, and the process of solidifying into filaments is called as cooling and forming. At the same time of cooling, due to the stretching effect of the spinneret, the melt stream is gradually refined before it is solidified. Cooling forming is completed in the spinning window, cooling air forced blowing out of the blowing window at the upper end of the spinning shaft can ensure uniform cooling conditions.

7, oiled

As the nascent fiber is more dry, easy to produce static electricity, and the filament between the poor cohesion, loose filaments, the friction coefficient, can not be post-processing. Therefore, to spin yarn to oil. Although different oiling positions are different when spinning with different processes, the purpose of oiling the oil can play a role in favor of yarn bundling, reduction of static electricity and improvement of smoothness. Conventional spinning oil tanker are used to oil, the cooling of the forming of silk through the corridor to reach the winding machine, the contact with the tanker finish oiling.

8, winding

Winding by the upper and lower godets, horizontal guide wire and friction roller cooperate with each other to complete. After the oil on the yarn through the upper and lower guide wire to change the direction of tension after adjustment by the yarn guide wound on the bobbin. The tube and the winding roller head contact pressure at a certain pressure through the friction drive to maintain the same linear velocity, the speed is the spinning speed. Winding tension on the cheese forming and annealing have an impact on tension. Winding tension, overfeed rate and finish are the three important factors in winding forming.

Fubon focus on research and development and production of chemical fiber equipment

Take you into the chemical fiber world

Learn more about spinning those things!

Changzhou Fubon Chemical Fiber Machinery Factory mainly produces: polypropylene spinning machine, polypropylene FDY spinning machine, polypropylene FDY production line, polypropylene FDY equipment, polypropylene FDY machinery, polyester POY spinning machine, polyester POY production line, polyester POY equipment, polyester POY machinery, FDY spinning machine, polyester FDY machine, polyester FDY equipment, polyester FDY production line, polyester FDY machine, nylon FDY spinning machine, nylon FDY production line, nylon FDY machinery, nylon FDY equipment, spandex spinning machine, spandex production line, spandex Equipment, spandex machinery, spinning special parts, polyester small experimental machine, polypropylene small experimental machine, nylon small experimental machine.

- Accelerate circular innovation in the textile industry to help enterprises better embrace

- What is polypropylene spinning machine equipment

- | Professionals need to think deeply about how to make themselves indispensable talents

- Kashgar textile and garment industry (Guangzhou) investment promotion meeting was held in

- High quality polypropylene FDY spinning machine looking for Fubon

- Jingzhou City organized the third centralized meeting of textile printing and dyeing enter

- Polypropylene spinning machine hot roller heating high efficiency and energy saving

- Workplace skills | Workplace people how to relax the mood, reasonable regulation of work e

- "Textile machinery and accessories double twisting machine terminology" and "Double twisti

- Polyester POY spinning machine manufacturers analyze the functional area of spinning machi