- Polypropylene spinning machine

- Polypropylene FDY equipment

- Polyester POY spinning machine

- Polyamide FDY common and high strength equipment

- Polyester FDY equipment

- Polyester high strength equipment

- polyester、Polyamide、 Polypropylene BCF equipment

- Small spinning machine

- All kinds of spinning special parts

- The exchange event on the digital and intelligent transformation and development of the textile and garment industry was held in Haicheng

- During the White Dew season, meticulous considerations for polypropylene spinning production

- Education shapes talents, and craftsmanship empowers the future. Grateful for teachers' kindness and nurturing of students, Fubang Machinery wishes all teachers a happy Teachers' Day!

- The grand selection ceremony for the 2025 China National Textile and Apparel Council Science and Technology Award - Mulberry and Hemp Scholar Award was held

- The years have been eventful, and the heroes sing their praises. Fubang Machinery warmly congratulates the 80th anniversary commemoration of the Victory of the War of Resistance against Japanese Aggression on its complete success!

- Contact:Mr. Huang Guofu

- Cel:0086-13901505556

- Fax:0086-519-83341119

- Email:czfb5556@126.com

- Add:No. 288-8 ChangLi Rd, Huangli Town, Changzhou, JS PRV.

The term spinning machine familiar

Many people understand her is limited to this

Xiaobian today we take an in-depth anatomical spinning machine

Quest its four major functional areas!

Polyester filament spinning positions include cutting dry, melting, spinning, cooling, winding, in addition to auxiliary unit heat medium system, hair system and oil system.

The post using screw extruder to pass through the drying qualified slice melt mixing, transport to the thermal insulation of the spinning box, measured by the metering pump, the melt flow to the precise pressure and high pressure through the filter layer by the spray Silicone silk discharge filament, in the spinning window body, by the constant temperature and humidity quantitative cooling air cooling and solidification, to wet the oil, the winding machine into a wire barrel.

Know spinning machine

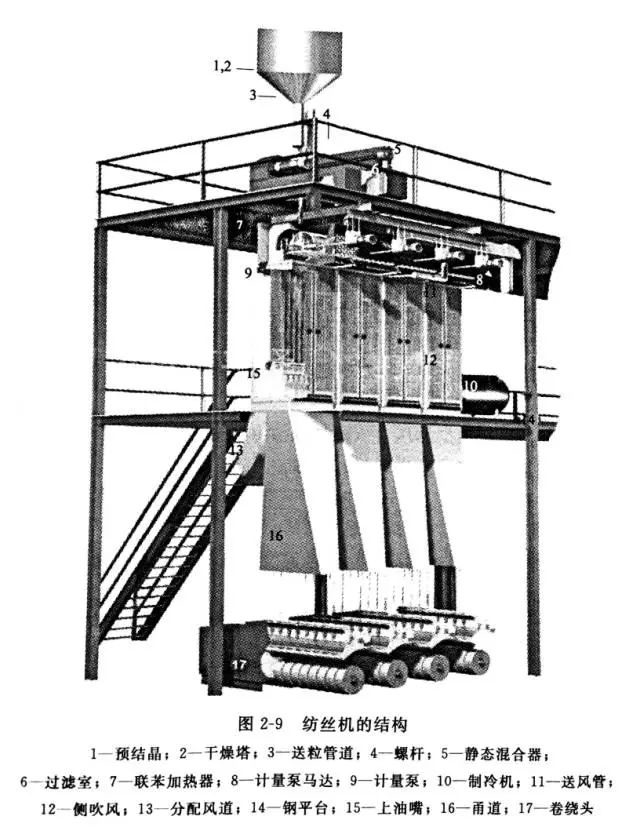

General spinning machine itself has 4 functional areas.

① high polymer melting device: screw extruder.

② melt delivery, distribution, spinning and insulation device: elbow, spinning box (melt distribution pipe, metering pump, spinning head assembly).

③ wire cooling device: spinning window and cooling sleeve.

④ silk collection device: to the wet oil institutions, guide wire structure, winding machine or by wire device.

First, the melting device

(1) role: the supply of solid materials, polymer melt, melt quantitative extrusion.

(2) screw three sections: feed section, compression section, metering section.

(3) screw extruder working principle: that the screw partition and material in the screw movement in various regions.

① feed zone (curing zone) and other deep-drawn screw.

② The first half (cooling zone) jacketed coil or screw core through the cooling water, <100 ℃ to prevent premature melting of materials and loop knot blocking material protection screw drive mechanism from heat.

③ second half (preheating zone) to prevent the material from the feed zone to the compression zone sudden temperature changes.

④ compression zone (melting zone) Gradient or sudden change Screw melt material (heating, shearing) and compression (smaller screw channel volume); the air or water vapor back to the feed zone.

⑤ metering area (homogenization zone) and other shallow screw.

Second, the melt delivery, distribution, spinning and insulation device

(1) Elbow: melt delivery pipe from the screw extruder to the spinning box (one end is connected to the outlet of the screw and the other is connected to the melt distribution pipe of the spinning machine) - Biphenyl-diphenyl ether The mixture is heated (melt insulation).

(2) spinning box: melt distribution pipe + biphenyl heating box + spinning pump and its transmission device + spinning head assembly.

① melt distribution pipe principle

② to ensure that the melt reaches the same distance from the spinning position of the melt in the distribution tube residence time is short; less folded back.

③ melt distribution pipe in the form of branch, radiation.

(3) spinning box heating (biphenyl heating box)

(4) metering pumps, high temperature gear pump.

(5) Spinning head assembly

① role: Filtering the melt to prevent plugging the melt hole spinneret sufficiently mixed to reduce the difference in melt viscosity, the melt evenly dispersed into each hole in the spin hole to form a fine melt flow.

② structure: spinneret + melt distribution plate + melt filter material + assembly of the combination of sleeve.

Third, the spinning box heating (biphenyl heating box)

① role: on the melt distribution pipe, metering pumps, spinning head assembly insulation heating effect.

② way: biphenyl - diphenyl ether heat carrier (biphenyl / diphenyl ether a 26.5% / 73.5%), with electric heating rods.

③ Insulation: 80 ~ 100mm insulation layer, filled with superfine glass fiber or other insulation materials.

Fourth, silk cooling device

(1) Spinning windows: The filaments are only cooled by directional, quantitative and qualitative air flow during cooling. The cooling rate is uniform and the fiber coagulation position is fixed (not affected by ambient air flow).

(2) slow cooling chamber: the lower set before and after the two flapper, so that it is separated from the cooling spinning cylinder, the upper latch, the slow cooling zone formed under the nozzle plate; length 30 ~ 200mm; to prevent the cooling air cooling Spinneret surface, reduce the birefringence of the winding wire, improve the stretchability.

Five, silk collection device

The structure of the spinning machine is shown in Figure 2-9.

Fubon focus on research and development and production of polyester POY spinning machine

Take you into the chemical fiber world

In-depth understanding of spinning machine those things!

Changzhou Fubon Chemical Fiber Machinery Factory mainly produces: Polyester POY spinning machine, polypropylene spinning machine, polypropylene FDY spinning machine, polypropylene FDY production line, polypropylene FDY equipment, polypropylene FDY machinery, polyester POY spinning machine and Polyester POY spinning machine.

- Education shapes talents, and craftsmanship empowers the future. Grateful for teachers' ki

- The exchange event on the digital and intelligent transformation and development of the te

- During the White Dew season, meticulous considerations for polypropylene spinning producti

- The grand selection ceremony for the 2025 China National Textile and Apparel Council Scien

- The years have been eventful, and the heroes sing their praises. Fubang Machinery warmly c

- The romantic Qixi Festival is here! Fubang Machinery, with its exquisite craftsmanship, co

- The 2025 Qilu Fashion Conference was held in Jinan

- Comprehensive Analysis of Core Components of polypropylene spinning machines: From Screw E

- The Start of Autumn has arrived, and the coolness of autumn begins. From the solar terms t

- The Academic Conference on Intelligent Manufacturing and Industrial Upgrading of China's S