- Polypropylene spinning machine

- Polypropylene FDY equipment

- Polyester POY spinning machine

- Polyamide FDY common and high strength equipment

- Polyester FDY equipment

- Polyester high strength equipment

- polyester、Polyamide、 Polypropylene BCF equipment

- Small spinning machine

- All kinds of spinning special parts

- Fubon 2024 wonderful review | Dragon Teng four seas family music, snake dance Kyushu everywhere new, I wish you all the best, accompanied by good luck!

- Textile industry alarm sound | EU sanctions escalation, trade winter is coming, how to break through the textile industry?

- China Shaoxing Textile industry new quality productivity development Forum was held

- Polypropylene spinning machine is the pioneer of excellence in the field of chemical fiber manufacturing

- Management methods | As new managers face many challenges with their changing roles, managers must learn strategies not to detente

- Contact:Mr. Huang Guofu

- Cel:0086-13901505556

- Fax:0086-519-83341119

- Email:czfb5556@126.com

- Add:No. 288-8 ChangLi Rd, Huangli Town, Changzhou, JS PRV.

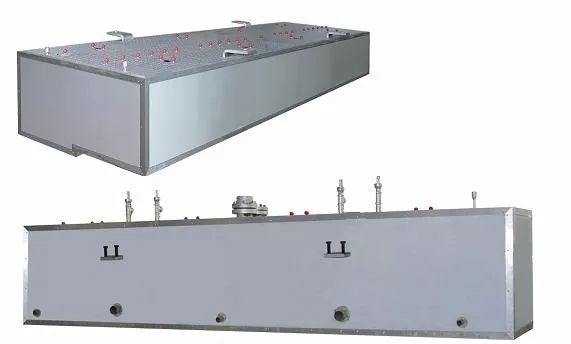

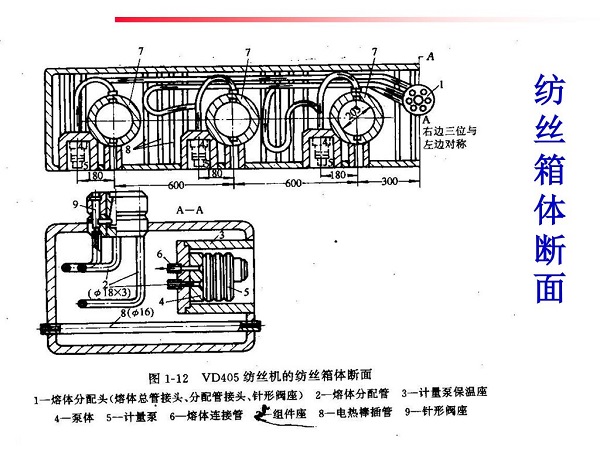

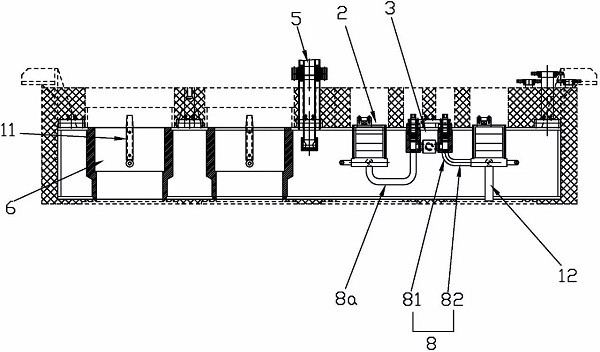

The spinning box body is a rectangular heating body heating box which is provided with a melt distribution pipe, a dosing pump, a component and a box body to coat the heat insulation material, so as to insulate the melt. The box body is provided with a heating medium electric heating That is, the heat medium boiler, with the gas phase heat medium circulation, the spinning box body of the melt distribution pipe, metering pumps, spinning components from the insulation, heating effect.

The length of the melt distribution pipes at the entrance of the melt to each spinning site in the spinning box is equal to each other to avoid differences in the resistance of the pipes between the spinning stations and to ensure the melt viscosity, And its uniform temperature, to ensure uniform and stable spinning quality.

Spinning melt production line polymer melt in the process of transport and flow, due to the loss of heat will lead to the melt temperature drop and poor mobility affect the flow and distribution of the melt, in order to ensure the process needs to be in the spinning box Increase the heating system. The function of the spinning box heating system is to maintain or control the temperature of the melt so that it has suitable flow properties and pressures to meet the process requirements.

Spinning box heating

Most spinning boxes are using electric heating, the heating power of heating zones are generally configured according to an equal temperature distribution, that is, the power of each heater is the same, the distance between the heater is the same. However, due to the different cooling conditions (or heat load) during operation, the adjacent heating zones affect each other. In actual operation, the temperature setting values may also be different. The actual working condition of the heater in each heating zone (Load rate) is not the same.

The total heating power of the spinning box is related to the temperature of the melt, the flow of the melt, that is to say the throughput of the spinning system, the higher the temperature of the melt, the greater the flow of melt, the greater the heating power required . However, the actual consumed power is only close to the installed power during the warming phase, and the holding phase after reaching the set temperature will be far less than the installed power.

Spinning box temperature control

The temperature control system of the spinning box adopts closed-loop PID control, and each temperature zone forms an independent temperature control system. As the melt temperature difference directly affects the quality of the product, the heating system requires a higher temperature control accuracy, usually ± 1 ℃. Because of the higher temperature of the melt, the heating power of the spinning box is also larger, and the heating power of the box of 3.2m production line can reach about 60 to 100kw. However, the actual power consumption mainly relates to the melt flow rate, heat preservation and cooling status Related.

Spinning box insulation

The surface area of the spinning box is very large. A temperature difference of 200-300 DEG C may exist between the spinning box and the surrounding environment during operation. If not, the heat treatment will not only dissipate a large amount of heat energy and increase the production cost, but also affect the production environment. Increase employee operating intensity. Under normal circumstances, the new spinning box after a trial run, after thermal fastening, it should be timely insulation. Non-combustible inorganic insulation materials with working temperature higher than 300 ℃ should be selected, such as rockwool and aluminum silicate insulation felt. Fill method is generally used in the country, that is, with metal insulation material to protect the shell and the gap between the box filled. After insulation treatment, the outer surface of the spinning box body temperature can be generally controlled at about 60 ℃.

Spinning box on the detection and protection devices

The melt temperature and pressure sensors mounted on the spinning box are used to detect and protect the spinning box. Each individual heating zone is an independent temperature control system, equipped with a temperature sensor for temperature measurement and control in each heating zone. On both sides of the spin box of the meltblown system, there are also sensors for drafting the airflow duct and for measuring the temperature and pressure of the drafting airflow. In addition to the spin box at the melt inlet is generally also equipped with a temperature sensor and pressure sensor for displaying the melt temperature, which pressure sensor is only used to show the pressure of the melt and overpressure protection provided overpressure signal.

In order to prevent the pressure in the spin box body exceeds the set value of the accident occurred, some spinning box body is equipped with explosion-proof tube communicating with the melt channel. When the pressure exceeds the set value, the explosion-proof tube in the film will automatically burst, pressure relief, to protect the safety of the spinning box. For this type of spinning box with explosion-proof devices, care must be taken to avoid the potential danger of melt splashes when the film is automatically blasted.

▲ spinning box melt channel structure

Fubon focus on research and development and production of chemical fiber equipment

Take you into the chemical fiber world

In-depth understanding of spinning machine those things!

Changzhou Fubon Chemical Fiber Machinery Factory mainly produces Polypropylene spinning machine, Polypropylene FDY Spinning Machine, Polypropylene FDY Production Line, Polypropylene FDY Equipment, Polypropylene FDY Machine, Polyester POY Spinning Machine, Polyester POY Production Line, Polyester POY Equipment, Polyester POY Machinery, FDY Spinning Machine, Polyester FDY Spinning Machine, Polypropylene spinning machine, Polyester FDY Production Line, Polyester FDY Machinery, Nylon FDY Spinning Machine, Nylon FDY Production Line, Nylon FDY Equipment, Spandex Spinning Machine, Spandex Production Line, Spandex Equipment, Spandex Machinery, Spinning Parts, Dacron Small Testing Machine, PP Small Testing Machine, Nylon Small Testing Machine, Polypropylene spinning machine.

- Fubon 2024 wonderful review | Dragon Teng four seas family music, snake dance Kyushu every

- Textile industry alarm sound | EU sanctions escalation, trade winter is coming, how to bre

- China Shaoxing Textile industry new quality productivity development Forum was held

- Polypropylene spinning machine is the pioneer of excellence in the field of chemical fiber

- Management methods | As new managers face many challenges with their changing roles, manag

- We will vigorously build advanced manufacturing clusters to promote high-quality economic

- The heating part of the polypropylene spinning machine is called the hot roll

- Textile news | The textile industry is making efforts in the field of digital science and

- 2024 thousands of customers into Shengze men's fabric special matchmaking meeting was held

- Polypropylene small testing machine covers a small area