- Polypropylene spinning machine

- Polypropylene FDY equipment

- Polyester POY spinning machine

- Polyamide FDY common and high strength equipment

- Polyester FDY equipment

- Polyester high strength equipment

- polyester、Polyamide、 Polypropylene BCF equipment

- Small spinning machine

- All kinds of spinning special parts

- The Winter Solstice marks the rise of Yang energy. In Fubon spinning machines, the Winter Solstice code is revealed, a dialogue of craftsmanship spanning a thousand years

- The establishment conference of Guangzhou Modern Textile and Garment New Quality Productivity Research Institute and the co-construction conference of the textile industry innovation ecosystem were held

- The key points of control in the polypropylene FDY spinning machine process and their relationship with quality

- A Guide for Managers to Break Through: Empowerment Rather than Control: Helping Enterprises Bid farewell to Internal Friction and Activate the Intrinsic Motivation of Teams!

- The 2025 Textile and Garment Innovation Annual Conference and the Gongqingcheng Down Industry Development Conference came to a successful conclusion

- The technological upgrade of polypropylene FDY spinning machines empowers the production of diversified chemical fibers

- Contact:Mr. Huang Guofu

- Cel:0086-13901505556

- Fax:0086-519-83341119

- Email:czfb5556@126.com

- Add:No. 288-8 ChangLi Rd, Huangli Town, Changzhou, JS PRV.

As the last process of spinning and the first process of weaving, the winding tube plays the role of "bridge" which is the foundation of the spinning and weaving and plays an important role in the textile field. In the case of a winding machine failure, it should be based on primary and secondary factors to find out the reasons for failure and solutions.

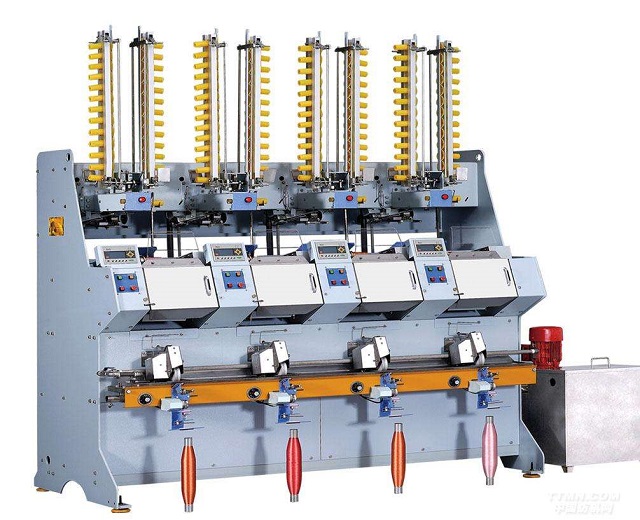

▲ Single spindle winding machine

1, tube yarn library does not turn

In the normal winding, the tube unwinding is completed, the detection device detects and discriminates the signal, and drives the transmission mechanism to move the spindle base to the empty tube conveyor belt and empty the empty tube into the conveyor belt. Stepper motor through the transmission rod to ratchet a tooth, tube yarn library rotation angle, the full yarn into the spindles spindles, and then inserted into the spindles spindle seat to work position.

As the ratchet parts are lint or loop winding wound, so that the ratchet can not drive the ratchet rotation, so there yarn failure does not turn. As long as the yarn library parts removed, lint or silk can be cleared to resume normal. In weekly cleaning with compressed air, as long as the clean place will be to prevent the failure occurred.

2, tube yarn frequently replaced tube device to retire

This failure is caused by the contaminated surface of the probe device, failure. As long as the test surface can be wiped clean. Regular cleaning of the detection section of the yarn inspection device is the best way to prevent this failure.

3, scissors not sharp

If the scissor is not sharp can not cut the yarn, then the yarn sucked by the small nozzle will be folded into double yarn in the fixed nozzle, so that when cut through the yarn clearer, so repeated, resulting in not normal production , And to increase energy consumption. When the repair part of the scissors removed, for a new pair of scissors can be. Not sharp scissors do not discard, can be sent to mechanical maintenance processing workshop (referred to as the mechanic workshop) grinding sharp after continued use.

4, tension device malfunction

The tensioning device provides the yarn with the proper tension through the tension disc. Tension disc is divided into pressure plate and stationary plate. Static disk is fixed, the pressure plate can be axial and swinging. When the pressure plate is rewound wound, its motion blocked, resulting in instability in tension, uneven winding density, often appear broken phenomenon. Maintenance should be demolished according to the operation, the return wire and other debris can be cleaned.

5, big mouth air leakage

When the large nozzle at zero, with a yarn on the mouth next to a large nozzle, if the yarn is sucked into the large nozzle, then the large nozzle air leakage. Large nozzle leakage will not only result in energy waste, but also make other parts of the lack of pressure. Whether the suction nozzle is controlled by the big suction nozzle energy-saving flap on the damper. Open the big mouth suction cup suction, otherwise not suction.

Large suction nozzle air leakage is due to the living plate is closed and closed by lacunar plugs and imprudent caused, therefore, in the maintenance of the damper should be removed, the lint dust clean, and remove the trap to open the cylinder Piston, smear sealing grease, in order to achieve the role of sealing and lubrication. Damper installation is completed, to check again with the yarn is really airtight, and make sure to repair a good one.

6, splicing failure or splicing failure

Failing splices or failed splices are caused by a variety of causes. First, improper process design, splicing parameters unreasonable. Second, the position of the spindle is not correct, failed to dial into the splicer yarn. Third, the splicer lack of oil rotation is not flexible, ring leakage, splicing cover damaged or bouncing ineffective.

One reason is that artificial causes can change the splicing parameters, and then do the splicing test to test whether the splicing parameters are reasonable. The solution of the second reason is to unscrew the set screw on the adjusting rod and correct the position. The third reason is often the phenomenon, but also the focus of maintenance work, so maintenance can be carried out according to the specific circumstances, if necessary, can be added for the activities of oil.

7, yarn clearer failure

Clearer yarn is another key component affecting the yarn quality. Automatic winder usually use electronic yarn clearer, electronic yarn clearer is divided into two types of photoelectric and capacitive. To LOEPFE produced TK830 capacitive yarn clearer as an example analysis, if there is a mechanical wave tube yarn, yarn clearer will be in the grooved drum after a few turns, then change the yarn can resume normal production.

However, when the yarn clearer fails, frequent cuts occur within a short period of time, so that it is impossible to continue production. The troubleshooting method is to reset the yarn clearer, the number of reset should be more than twice in order to ensure that the reset is correct. If the reset is invalid, it can be concluded that the internal yarn clearer electronic damage, can be handled by the electrician.

8, Cartridge holding arm size chuck rotation is not flexible

The size of the yarn holding arm chuck are high-speed parts, the speed and the speed of the grooved cylinder close, so often bearing wear failure. Fault occurs, the cheese rotation difficult, yarn unevenly arranged, there will be an alarm, as long as the chuck within the bearing removed to replace the normal production can resume.

The above eight troubleshooting methods

You pointed out the direction of solving the problem

Let you remedy the problem to eliminate winder!

Changzhou Fubon Chemical Fiber Machinery Factory mainly produces Polypropylene spinning machine, Polypropylene FDY Spinning Machine, Polypropylene FDY Production Line, Polypropylene FDY Equipment, Polypropylene FDY Machine, Polyester POY Spinning Machine, Polyester POY Production Line, Polyester POY Equipment, Polyester POY Machinery, FDY Spinning Machine, Polyester FDY Spinning Machine, Polypropylene spinning machine, Polyester FDY Production Line, Polyester FDY Machinery, Nylon FDY Spinning Machine, Nylon FDY Production Line, Nylon FDY Equipment, Spandex Spinning Machine, Spandex Production Line, Spandex Equipment, Spandex Machinery, Spinning Parts, Dacron Small Testing Machine, PP Small Testing Machine, Nylon Small Testing Machine, Polypropylene spinning machine.

- The Winter Solstice marks the rise of Yang energy. In Fubon spinning machines, the Winter

- The establishment conference of Guangzhou Modern Textile and Garment New Quality Productiv

- The key points of control in the polypropylene FDY spinning machine process and their rela

- A Guide for Managers to Break Through: Empowerment Rather than Control: Helping Enterprise

- The 2025 Textile and Garment Innovation Annual Conference and the Gongqingcheng Down Indus

- The technological upgrade of polypropylene FDY spinning machines empowers the production o

- Textile News: Full-chain Efforts + Cross-border Breakthroughs + Talent Foundation - The Te

- The 2025 China Home Textile Fashion Innovation Conference grandly kicked off in Binzhou

- On the Important Role of Polypropylene Spinning Machines in Chemical Fiber Production

- Management Skills: Managing Problems = Managing Efficiency: Anchor the essence of manageme