- Polypropylene spinning machine

- Polypropylene FDY equipment

- Polyester POY spinning machine

- Polyamide FDY common and high strength equipment

- Polyester FDY equipment

- Polyester high strength equipment

- polyester、Polyamide、 Polypropylene BCF equipment

- Small spinning machine

- All kinds of spinning special parts

- Polypropylene FDY spinning machine is a key equipment for the production of high-performance fibers

- Several silk textile industry renewal projects in Shengze have started construction

- The Winter Solstice marks the rise of Yang energy. In Fubon spinning machines, the Winter Solstice code is revealed, a dialogue of craftsmanship spanning a thousand years

- The establishment conference of Guangzhou Modern Textile and Garment New Quality Productivity Research Institute and the co-construction conference of the textile industry innovation ecosystem were held

- The key points of control in the polypropylene FDY spinning machine process and their relationship with quality

- Contact:Mr. Huang Guofu

- Cel:0086-13901505556

- Fax:0086-519-83341119

- Email:czfb5556@126.com

- Add:No. 288-8 ChangLi Rd, Huangli Town, Changzhou, JS PRV.

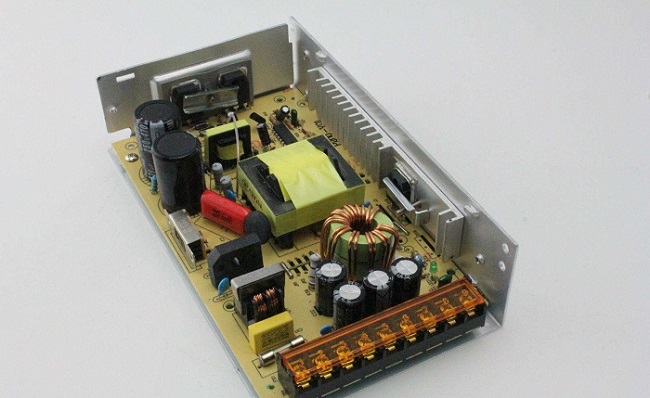

With the increasing automation of textile equipment, inverters and PLC circuit boards have become indispensable components for textile equipment. However, with the operation of the equipment for many years, circuit board failures occur from time to time, so that the company's maintenance costs continue to rise. Xiao Bian summed up some of the circuit board maintenance, component testing of the small experience and skills for everyone to share.

Switching power supply circuit board maintenance

After the power is burned, the insurance is the rectifier bridge, switch power supply integrated block (UC3842) or power supply filter capacitor and other damage.

After the switching power supply board is powered on, the voltage at both ends of the power filter capacitor is measured. After the power is turned off, the voltage at both ends of the power filter capacitor cannot disappear in a short period of time, which proves that the starting resistance of the switch tube is blocked.

The switching power supply board has no output, and the electrolytic capacitor of the circuit board can be replaced, so that a multiplier effect can be obtained.

The output voltage of the switching power supply board is unstable, which is caused by poor contact of the adjustable resistor on the switching power supply board or optocoupler of the voltage regulator block (T431).

The switch tube on the switching power supply board is often damaged, which may be due to the high-frequency spike capacitance or bad resistance of the switch tube.

When the inverter servo controller is powered on in the cold state, the display flashes digitally and cannot be operated. After a few minutes, it can be used normally and gradually becomes longer and longer. Most of the reasons are switching power supply once and twice. Leakage of the electrolytic capacitor on the side causes the capacitance to become smaller.

Measure the resistance of the resistor online and it should be less than or equal to the nominal resistance of the resistor. Normal, otherwise it is abnormal.

Carding dust control electrical PLC fault

If the power indicator is off, there is no output. After the on-line detection, the 2A fuse is blown, and the 1N4007 and 0.47VF/400 electrolytic capacitors are damaged. After replacing the fuse and 1N4007, if there is no 0.47VF/400 electrolytic capacitor, two 1VF and 400V electrolytic capacitors can be substituted in series to make the PLC work normally and the effect is good.

CPU test

The main conditions for the CPU work are 3 elements: normal working voltage and grounding; clock oscillation is normal; reset (clear) circuit is normal.

(1) Normal operating voltage and grounding

Any appliance must have power to work, and the CPU is no exception. It must be ensured that the power supply voltage between the CPU power supply pin and the ground pin is correct, and the CPU's requirement on the power supply is more strict, usually 5V±10%, which is the primary condition for the normal operation of the microprocessor.

(2) Clock oscillation is normal

The clock signal is the soul of CPU work. Only under the action of timing pulse signal, CPU can read instructions and execute instructions sequentially.

(3) Reset (clear) circuit is normal

The reset is to restore the CPU to a certain state. The actual completion is the initialization of the internal memory, so the reset voltage must be standard.

Reset, use a multimeter DC voltage file to test the reset point, in the switch state, there is no voltage, there is a clear voltage fluctuation is normal.

Oscillation circuit, most transistor oscillators, with a high pin voltage (2V or more) and low voltage on the other pin (a few tenths of a volt), collide with two transistor oscillator pins. If the high voltage pin is tested, the voltage changes significantly, indicating that the CPU The internal clock oscillation circuit is working properly.

According to the above maintenance tips

When you encounter related issues

You can try to solve it yourself

Save time and effort while

Helps enhance your maintenance skills!

Changzhou Fubon Chemical Fiber Machinery Factory mainly produces Polypropylene spinning machine, Polypropylene FDY Spinning Machine, FDY Spinning Machine, Polyester FDY Spinning Machine, Polypropylene spinning machine, Polyester FDY Production Line, Nylon FDY Spinning Machine, Spandex Spinning Machine, Spandex Equipment, Spinning Parts, Dacron Small Testing Machine, PP Small Testing Machine, Polypropylene spinning machine.

- Several silk textile industry renewal projects in Shengze have started construction

- Polypropylene FDY spinning machine is a key equipment for the production of high-performan

- The Winter Solstice marks the rise of Yang energy. In Fubon spinning machines, the Winter

- The establishment conference of Guangzhou Modern Textile and Garment New Quality Productiv

- The key points of control in the polypropylene FDY spinning machine process and their rela

- A Guide for Managers to Break Through: Empowerment Rather than Control: Helping Enterprise

- The 2025 Textile and Garment Innovation Annual Conference and the Gongqingcheng Down Indus

- The technological upgrade of polypropylene FDY spinning machines empowers the production o

- Textile News: Full-chain Efforts + Cross-border Breakthroughs + Talent Foundation - The Te

- The 2025 China Home Textile Fashion Innovation Conference grandly kicked off in Binzhou