- Polypropylene spinning machine

- Polypropylene FDY equipment

- Polyester POY spinning machine

- Polyamide FDY common and high strength equipment

- Polyester FDY equipment

- Polyester high strength equipment

- polyester、Polyamide、 Polypropylene BCF equipment

- Small spinning machine

- All kinds of spinning special parts

- The exchange event on the digital and intelligent transformation and development of the textile and garment industry was held in Haicheng

- During the White Dew season, meticulous considerations for polypropylene spinning production

- Education shapes talents, and craftsmanship empowers the future. Grateful for teachers' kindness and nurturing of students, Fubang Machinery wishes all teachers a happy Teachers' Day!

- The grand selection ceremony for the 2025 China National Textile and Apparel Council Science and Technology Award - Mulberry and Hemp Scholar Award was held

- The years have been eventful, and the heroes sing their praises. Fubang Machinery warmly congratulates the 80th anniversary commemoration of the Victory of the War of Resistance against Japanese Aggression on its complete success!

- Contact:Mr. Huang Guofu

- Cel:0086-13901505556

- Fax:0086-519-83341119

- Email:czfb5556@126.com

- Add:No. 288-8 ChangLi Rd, Huangli Town, Changzhou, JS PRV.

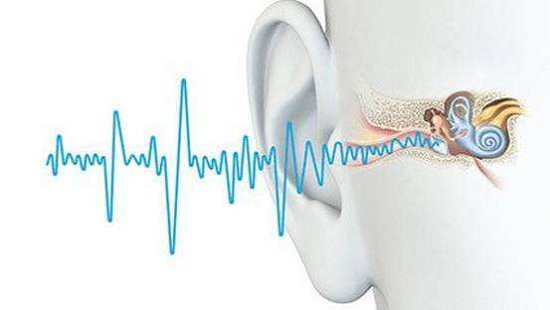

The textile industry production workshop has many equipments and is closely arranged, which causes the noise of the workshop to be large. The noise not only damages the health of the workers, but also greatly reduces the working ability and labor productivity of the workers. Effectively reduce the noise intensity of the workshop, improve the working environment of workers, reduce the pressure on recruitment, and also improve labor productivity and production efficiency.

Source of noise in the textile workshop

In general, most textile machines have periodic impact mechanisms that, when operated, cause vibration and low frequency noise by inertial forces, friction and working loads. When there is a gap in their joints, the impact will cause high frequency noise. The machine's aerodynamic system's fans operate with low-frequency aerodynamic noise, while the aerodynamic system's nozzles produce high-frequency aerodynamic noise.

Such as the transmission system of various textile equipment, that is, the transmission of gears and chains; the spinning spindle of spinning machine and spinning machine; the high frequency noise emitted by the bearing and the wire ring of the spindle; the low frequency and intermediate frequency noise generated by the fan; Noise generated by mechanical impact of the rib mechanism and the beating mechanism.

The significance of reducing noise in the textile workshop

Reducing the noise of the textile workshop, in addition to reducing its direct harm, has great social and economic significance. Create good working conditions for textile workshop staff, which will help improve labor productivity and production efficiency.

On the one hand, the increase in products produced per unit time shortens the consumption of working hours; on the other hand, it reduces the time that workers cannot work, thereby increasing the efficiency of total working hours and reducing the cost for medical treatment.

Five measures to reduce noise

1. Systematic principle of noise reduction

Preventing noise and acoustic vibration is a complex problem for ensuring normal sound conditions in the workshop. This requires a comprehensive set of measures to implement the system. To provide this, it is necessary to make a reasonable layout at the beginning of the design of the plant; to reduce the vibration of the machine at the sound source, and to install sound-absorbing equipment in the workshop and use a systematic project such as personal noise-proof products to ensure .

2. Reasonable plant layout

Properly arranging the workshops with noisy equipment in the factory area, especially the correct arrangement of the noisy sections in the workshop, can ensure that most people who are not directly related to the noisy equipment maintain their normal working conditions. At the time of planning, there are noisy workshops that should be concentrated in one or two places and placed in the downwind of the enterprise area boundary.

Reasonable layout and sound absorption, sound insulation and noise reduction in the factory. Cost-effective enclosures are used in the design to make porous sound-absorbing finishes and sound-absorbing and sound-insulating in the ceiling and wall of the workshop. , vibration damping and other devices to reduce noise in the workshop. Such as aluminum sound-absorbing panels for ceilings and walls, and so on.

3. Innovative structure of textile machinery and equipment

The way of noise reduction processing should first be reduced from the sound source. The new low-noise equipment is designed at the beginning of the equipment design to adopt the structure of the new machine equipment or to change the structure of the combined components with high noise, to reduce the dynamic load, eliminate the impact of the machine and improve the manufacturing precision. Good results can be obtained by changing the characteristics of the motion, the stiffness and the form of the transmission.

4, should pay attention to the textile process

To reduce the noise of the sound source, the industrial and transportation industries can use low-noise production equipment and improve the production process, or change the movement mode of the noise source, such as the shuttle rod, the 36-cone, the shuttle, the belt and the main sounding parts. The treatment is carried out, and the material of the member is replaced, for example, the nylon shuttle is used instead of the wooden shuttle, the nylon 36 toothed wheel is used instead of the cast steel gear, and the composite nitrile damping skin knot is used instead of the original nitrile sheath to reduce the noise.

In addition, further noise reduction effects can be obtained by inserting a damping layer on some components, or reducing the running speed of the loom, and installing a buffer device.

5, hierarchical management, hierarchical protection

In areas where outdoor control, design rooms, workshops, or employees work long-term, the intensity of noise is low; in the warehouse or few people go to the workshop or open space, the noise is slightly higher. In short, there should be some difference in the noise of different times, different locations, different natures and different durations.

The noise protection of the recipient or the sounding organ, if no measures can be taken on the sound source and the transmission route, or the acoustic measures taken still do not achieve the desired results, it is necessary to take protective measures against the recipient or the sounding organ. Workers with long-term occupational noise exposure can wear ear protectors such as earplugs, earmuffs or helmets. There are many people in the weaving workshop, and it is reasonable to take personal protective measures.

Changzhou Fubang Chemical Fiber Machinery Factory mainly produces: polyester industrial yarn spinning combined machine, polyester POY spinning machine, polypropylene FDY spinning machine, polypropylene FDY production line, polypropylene FDY equipment, polypropylene FDY machinery, polyester industrial yarn spinning combined machine, Polyester FDY spinning machine, polypropylene spinning machine, polyester FDY production line, polyester FDY machine, nylon FDY spinning machine, polyester industrial yarn spinning machine.

- Education shapes talents, and craftsmanship empowers the future. Grateful for teachers' ki

- The exchange event on the digital and intelligent transformation and development of the te

- During the White Dew season, meticulous considerations for polypropylene spinning producti

- The grand selection ceremony for the 2025 China National Textile and Apparel Council Scien

- The years have been eventful, and the heroes sing their praises. Fubang Machinery warmly c

- The romantic Qixi Festival is here! Fubang Machinery, with its exquisite craftsmanship, co

- The 2025 Qilu Fashion Conference was held in Jinan

- Comprehensive Analysis of Core Components of polypropylene spinning machines: From Screw E

- The Start of Autumn has arrived, and the coolness of autumn begins. From the solar terms t

- The Academic Conference on Intelligent Manufacturing and Industrial Upgrading of China's S